The World Wide Web has some excellent sites which cover the full history of audio recording. There are pictures and sound clips created on equipment used from the late 19th century and later. References to just a few of those sites are given below.

The brief comments here focus specifically on

the

process of encoding information on different media, starting

with the cylinders of Thomas Edison's first phonograph. The

cylinders seen at the left were created acoustically, that is, a

stylus mounted on a vibrating diaphragm cut a groove in the

cylinder as it rotated. The

groove was deeper or

shallower depending on the

position of the vibrating

diaphragm. The diaphragm was set in vibration by sound waves sent

down and concentrated in a horn connected to it. A principal

difference between the recorders which cut the groove and the

phonograph which played them back is that there was a rotating

screw on the recorder (or cutting lathe) which governed the position of the cutting stylus. Other

than

that, the very earliest players looked a lot like the recorders which

created the acoustically cut groove. It was common practice for

soloists to run up to the recording horn so as to achieve a higher vibration (hence, volume) going

into

the stylus cutting the groove. An example of an early cylinder phonograph is shown at right.

The brief comments here focus specifically on

the

process of encoding information on different media, starting

with the cylinders of Thomas Edison's first phonograph. The

cylinders seen at the left were created acoustically, that is, a

stylus mounted on a vibrating diaphragm cut a groove in the

cylinder as it rotated. The

groove was deeper or

shallower depending on the

position of the vibrating

diaphragm. The diaphragm was set in vibration by sound waves sent

down and concentrated in a horn connected to it. A principal

difference between the recorders which cut the groove and the

phonograph which played them back is that there was a rotating

screw on the recorder (or cutting lathe) which governed the position of the cutting stylus. Other

than

that, the very earliest players looked a lot like the recorders which

created the acoustically cut groove. It was common practice for

soloists to run up to the recording horn so as to achieve a higher vibration (hence, volume) going

into

the stylus cutting the groove. An example of an early cylinder phonograph is shown at right.

Standard-size cylinders, which tended to be 4.25" long and 2.1875" in diameter, were 50

cents each

and typically played at 120 r.p.m. The early cylinders had two significant problems. The first

was

the

short duration of material recorded, usually around 2 minutes. This necessarily narrowed the field

of

what could be recorded. The second problem was that no mass method of duplicating cylinders

existed. Most often, performers had to repeat their performances when recording in order to

produce

a quantity of cylinders. This was not only time-consuming, but costly.

A process for mass-producing duplicate wax cylinders was put into effect in 1901. The

cylinders were

molded, rather than engraved by a stylus, and a harder wax was used. The process was referred to

as Gold Moulded, because of a gold vapor given off by gold electrodes used in the process.

Sub-masters were created from the gold master, and the cylinders were made from these molds.

From

a single mold, 120 to 150 cylinders could be produced every day. By mid-1904, the savings in

mass

duplication was reflected in the price for cylinders which had been lowered to 35 cents each.

Beveled

ends were made on the cylinders to accommodate titles. Columbia, one of Edison's chief

competitors,

abandoned the cylinder market in 1912. The original Edison cylinders were cut with vertical

"mountains and valleys," rather than lateral "wiggles" as pioneered by Victor. Supporters of the

vertical cut argued that it produced a superior sound. The popularity of cylinders peaked around

1905 largely because discs

were much easier to mass

1905 largely because discs

were much easier to mass

produce. Edison conceded to

this reality in 1913

when he announced the manufacture of the Edison

Disc Phonograph. The Edison Company did not

desert its faithful cylinder customers, however, and

continued to make cylinders until 1929. The Edison

Company had been fully devoted to cylinder

phonographs, but, concerned with discs' rising

popularity, Edison and his associates began to develop

their own disc player and discs in secret, but Edison

decided to retain the vertical vibrations (mountains and

valleys) on his discs. It was many years before the

lateral cut was accepted as superior largely because of the effect of lower average force acting in

the

direction of the vibration. Often the playback stylus (or needle, as it was called) had a higher

than

necessary mass behind it in the form of a kind of snail- or spiral-shaped expanding hollow metal

tube the air hole

of

which finally fed into the base of the horn. The force exerted on the cylinder by that spiral tube,

which could pivot so as to allow the stylus to rise and fall a little with the imperfect radius of the

rotating cylinder, was not carefully controlled in early phonographs and

ended up producing more wear on a vertically cut

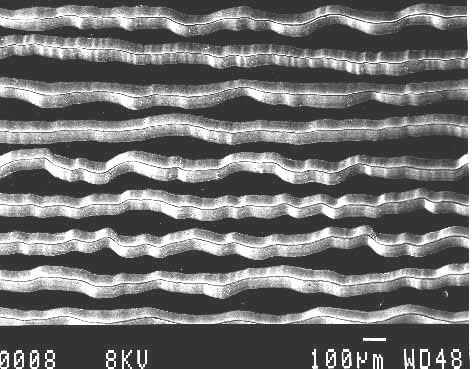

groove. The laterally cut groove (with "wiggles") is

shown at left and right. The force in the direction of

playback (back and forth) was little more than the

springiness of the playback stylus in the direction of the

wiggle of the groove. Whatever force produced wear

at the bottom of the groove did not, at least in principal,

produce any vibration (even though the noise of such

playbacks testifies to there being all kinds of audio

"leakage" from rough groove bottoms). Treat yourself

to the sound of some early cylinder recordings:

produce. Edison conceded to

this reality in 1913

when he announced the manufacture of the Edison

Disc Phonograph. The Edison Company did not

desert its faithful cylinder customers, however, and

continued to make cylinders until 1929. The Edison

Company had been fully devoted to cylinder

phonographs, but, concerned with discs' rising

popularity, Edison and his associates began to develop

their own disc player and discs in secret, but Edison

decided to retain the vertical vibrations (mountains and

valleys) on his discs. It was many years before the

lateral cut was accepted as superior largely because of the effect of lower average force acting in

the

direction of the vibration. Often the playback stylus (or needle, as it was called) had a higher

than

necessary mass behind it in the form of a kind of snail- or spiral-shaped expanding hollow metal

tube the air hole

of

which finally fed into the base of the horn. The force exerted on the cylinder by that spiral tube,

which could pivot so as to allow the stylus to rise and fall a little with the imperfect radius of the

rotating cylinder, was not carefully controlled in early phonographs and

ended up producing more wear on a vertically cut

groove. The laterally cut groove (with "wiggles") is

shown at left and right. The force in the direction of

playback (back and forth) was little more than the

springiness of the playback stylus in the direction of the

wiggle of the groove. Whatever force produced wear

at the bottom of the groove did not, at least in principal,

produce any vibration (even though the noise of such

playbacks testifies to there being all kinds of audio

"leakage" from rough groove bottoms). Treat yourself

to the sound of some early cylinder recordings:

Click here to listen to some

cylinder recordings

and

Click here to listen to a

vertically cut disc.

By the middle of the 1920s

discs were being recorded at a variety of speeds. Although 78 rpm was

said to be the industry standard, there was great variability in recording speeds for many years.

English Columbia routinely used 80 rpm into the 1920s. Other companies adopted speeds which

varied from 74 to 84 rpm.

By the middle of the 1920s

discs were being recorded at a variety of speeds. Although 78 rpm was

said to be the industry standard, there was great variability in recording speeds for many years.

English Columbia routinely used 80 rpm into the 1920s. Other companies adopted speeds which

varied from 74 to 84 rpm.

Around 1948 the vinyl record was born, that is the first

twelve inch "long play" (LP) microgroove records that played

at 33 1/3 rpm for up to 30 minutes per side, and seven inch

45 rpm singles and Extended Plays. The format was capable

of producing full frequency range. Claims of 20 Hz to 20,000 Hz were common, though the fall-

off in volume at either end seemed always either to be conveniently ignored or stated in the unit

decibels and in a manner which meant very little to the average audiophile. Still, recordings on a

vinyl base with the improved light weight pickup arms and styli offered a remarkable

improvement

in audio quality over the old 78s . These vinyl records were produced in a similar way

to

the Shellac 78s, that is, they were pressed from plates produced from a master. By the time LPs

appeared, recording on magnetic tape had enjoyed some considerable development and

electronic amplifiers produced consistently high sound quality throughout the recording process.

The

first vinyl disc offered only monaural sound (not stereo) which emanated from a laterally cut

groove of constant

width

as in the images above. Note in the right image above how close one groove comes at several

points to the next. A

particularly

loud passage sometimes produced sufficiently large "wiggles" to break over into an adjacent

groove,

so in order not to have to limit the loudness, a system of "dynamic separation" was developed to

detect the loudness on

the

master tape a distance ahead equal to one revolution of the disc so that the cutting stylus could be

moved further away from the previous groove before the volume increased. Even so,

bleed-across

was often evident. That is, a loud passage followed by a soft one could be heard one revolution

before it arrived because of slight compression of the previous groove by the stylus cutting the

next

adjacent groove. This was most commonly apparent in at the beginning of any disc the opening

passage of which was quite loud and could be heard at a much lower volume one revolution

before it arrived.

Monaural discs required information to be stored in a

lateral cut moving back and forth parallel to the surface of

the record. Stereo was made possible by cutting the

groove in a manner which "encoded" the left and right

channels in motion at right angles to each other but

diagonal to the surface of the disc. Both the cutting coils of the cutting lathe

and pickup coils of the stereo turntable or phonograph were arranged as shown in the figure at

the left. The signals going into the cutting coils (and then picked up by the playback coils)

corresponded to signals representing what would be heard by one's left and right ears. In

principle, stylus motion in one direction would produce no motion in the other because the two

were at right angles to each other. In practice there was always a little "cross-over" from one

channel to the other. Stereo sound was at first achieved with two microphones, often placed

close together and pointed at the performing group in a

manner meant to approximate one's sensory experience. The signals were picked up, amplified

and fed onto two tracks on a tape

recorder. Soon that primitive technique evolved into multi-track master tape recordings with

subsequent

changes made in an editing room to produce more pleasant effects on each channel. In any case,

a stereo disc ended up having to use both the lateral cut

pioneered by the Victor Company and the vertical cut first introduced by Edison, but the high

level

of noise which plagued the early shellac discs had been

largely eliminated by the smoother vinyl plastic of which the disc was made. Note that the

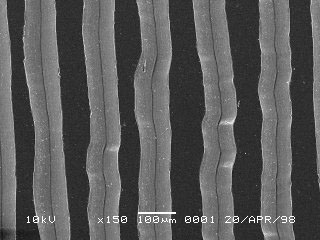

width of the grooves seem to change a bit in the image at

the right. There are wide and narrow regions. That is

caused by the V-shaped cutting stylus moving up and down

as well as back and forth. In particular, look at the place on

the lower middle right where the groove seems almost to

disappear. That particular point would be a prime candidate

for "skipping", a common phenomenon with discs in general

in which even the slightest jarring would cause the stylus to

jump out of the groove and to fall into another nearby groove.

Monaural discs required information to be stored in a

lateral cut moving back and forth parallel to the surface of

the record. Stereo was made possible by cutting the

groove in a manner which "encoded" the left and right

channels in motion at right angles to each other but

diagonal to the surface of the disc. Both the cutting coils of the cutting lathe

and pickup coils of the stereo turntable or phonograph were arranged as shown in the figure at

the left. The signals going into the cutting coils (and then picked up by the playback coils)

corresponded to signals representing what would be heard by one's left and right ears. In

principle, stylus motion in one direction would produce no motion in the other because the two

were at right angles to each other. In practice there was always a little "cross-over" from one

channel to the other. Stereo sound was at first achieved with two microphones, often placed

close together and pointed at the performing group in a

manner meant to approximate one's sensory experience. The signals were picked up, amplified

and fed onto two tracks on a tape

recorder. Soon that primitive technique evolved into multi-track master tape recordings with

subsequent

changes made in an editing room to produce more pleasant effects on each channel. In any case,

a stereo disc ended up having to use both the lateral cut

pioneered by the Victor Company and the vertical cut first introduced by Edison, but the high

level

of noise which plagued the early shellac discs had been

largely eliminated by the smoother vinyl plastic of which the disc was made. Note that the

width of the grooves seem to change a bit in the image at

the right. There are wide and narrow regions. That is

caused by the V-shaped cutting stylus moving up and down

as well as back and forth. In particular, look at the place on

the lower middle right where the groove seems almost to

disappear. That particular point would be a prime candidate

for "skipping", a common phenomenon with discs in general

in which even the slightest jarring would cause the stylus to

jump out of the groove and to fall into another nearby groove.

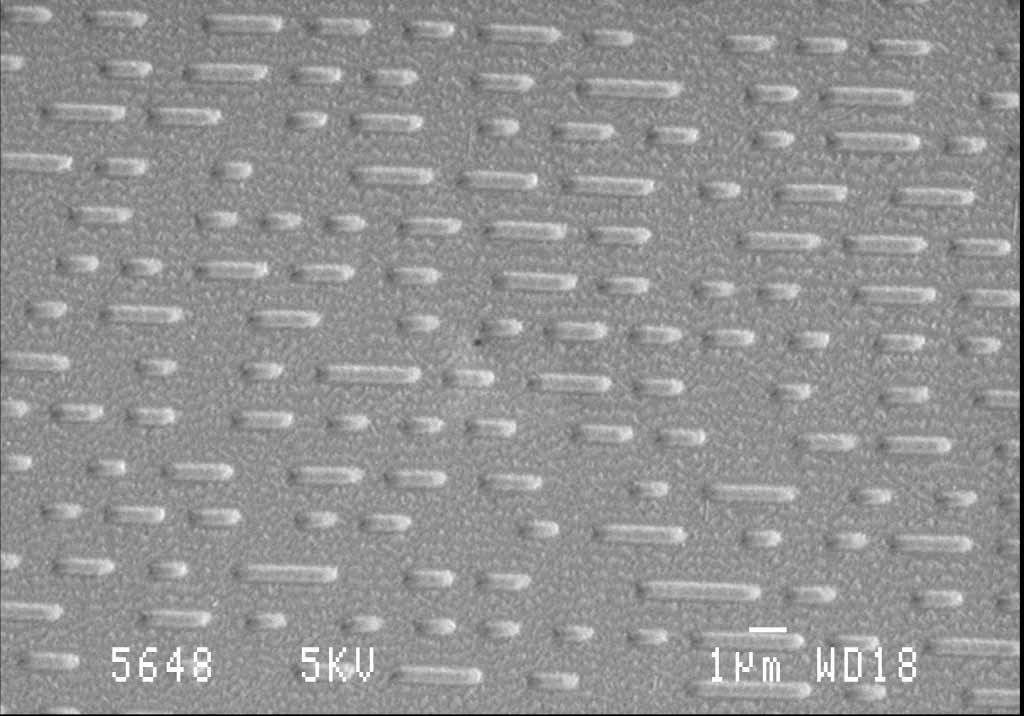

In 1983 digital recording technology became available for domestic use in the form of the Compact Disc (CD). Instead of recording the digital data on a magnetic medium, the stream of data is stored as tiny pulses on an aluminium disc coated in plastic. The data are then read using a laser

beam, thus eliminating physical wear on the discs. CD

technology has settled on a 16-bit audio "byte."

beam, thus eliminating physical wear on the discs. CD

technology has settled on a 16-bit audio "byte."

The bits in the byte are in the form of indentations in the disc

produced (initially at least)

by laser pulses. Note the

single commercially

produced melted pulse in a

disc surface at the left.

When linked together to

produce a series of audio

"bytes" the surface of the disc looks like the image at the right.

Recently, equipment to

produce one's own CDs has appeared on

the market at prices affordable by the average PC owner.

Several formats are available, one to produce audio CDs and

another to produce rewritable CDs offering a format which

appears no different in one's directory than that shown by a fixed

drive or floppy diskette. It is claimed that the pits produced by

home equipment

are not quite as

clean as

professional

masters. An

example of such a

claim is shown at the left.

Recently, equipment to

produce one's own CDs has appeared on

the market at prices affordable by the average PC owner.

Several formats are available, one to produce audio CDs and

another to produce rewritable CDs offering a format which

appears no different in one's directory than that shown by a fixed

drive or floppy diskette. It is claimed that the pits produced by

home equipment

are not quite as

clean as

professional

masters. An

example of such a

claim is shown at the left.

All that having been said, here is a link to a Real Media

file (converted from a digital CD) giving the first

second or two of the opening bars of Mozart's "Eine

Kleine Nachtmusik" (A little night music).

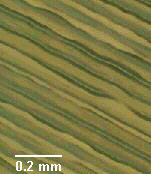

The sonogram or image of the vibrations of this music is shown at the right above. Be

cognizant that this "image" of the sound in the opening passage is of the original uncompressed

digital .WAV file created from a commercial CD of the piece, not

the

compressed .RM or Real Media file which you hear if you clicked on the link.

The first violin part is shown at the left to illustrate the coincidence between the size of the

"blips"

on the sonogram above and the note length in the music. The quarter notes are shown as large

blips and the eighths as small ones. The total time for a quarter note and an eighth rest is three

times that of an eighth note, as one would expect.

The first violin part is shown at the left to illustrate the coincidence between the size of the

"blips"

on the sonogram above and the note length in the music. The quarter notes are shown as large

blips and the eighths as small ones. The total time for a quarter note and an eighth rest is three

times that of an eighth note, as one would expect.

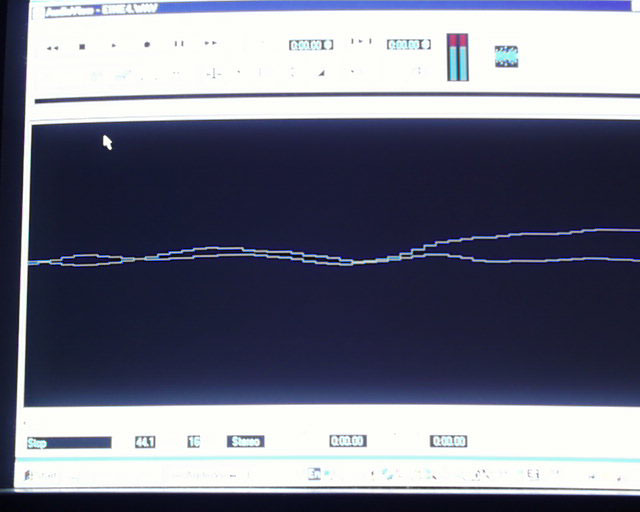

If a very tiny portion of this sonogram is copied and pasted to another .WAV file, it looks

like

the

image below. Each of the traces represents one of the stereo channels. The image has been

enlarged so that you can see the steps in the digital encoding. This small fragment is only 54

bytes

long for each channel. The standard sample rate for commercial CDs is 44,100 samples per

second per channel, so this fragment could be heard in a little over one one-thousandth of a

second. Not nearly enough time to start it, go into the kitchen for a cup of coffee and expect to

hear the rest of it on your return!

Each byte is a fixed sampled value. The playback machine must take sequential values and do a

digital-to-analog conversion so that an average smooth function results. Compressed audio files,

such as MP3 and RM (Real Media) files, are the result of "shortcuts" effected by the

compression

software.

The audio signal of an uncompressed WAV file is analyzed "on the fly" during the compression

process and the barest amount of data describing a particular signal shape finds itself replacing

the

actual shape in the compressed file. An example of such a shortcut would be to approximate the

rise one sees from the middle to the right side of the screen using two or three bytes and a code

indicating the time required to effect the rise. By so doing 3-4 bytes would be required instead of

the 26 or so one can count from the distinct dip to the right side of the screen. Such a shortcut

would offer a compression ratio of 26:4 or about 6:1. Much higher rates of compression are

possible if one is willing to make greater sacrifices in audio quality.

Thanks to all the people who

put out an enormous amount of work in preparing Web pages from

which much material was taken. The Web pages I used for this offering may be found at the

following sites:

(History of the Edison Cylinder

Phonograph)

(History of the Edison Disc

Phonograph)

and others which have been removed from the Web since I first created this page in 2007.